Providence Medical Center Increases HVAC System Efficiency

Increasing Efficiency of Your HVAC System

If you’ve ever wondered if duct cleaning is effective, this case study by Henderson Engineers, Inc. should set the record straight. Henderson Engineers was asked to study the results of a duct and coil cleaning project by Midwest Duct cleaning at Providence Medical Center. They gathered information for this study from the original design as well as from readings taken before, during, and after the cleaning. This information has been used to calculate the approximate energy savings based on the increased performance of the system. The results proved duct cleaning increases a system’s efficiency.

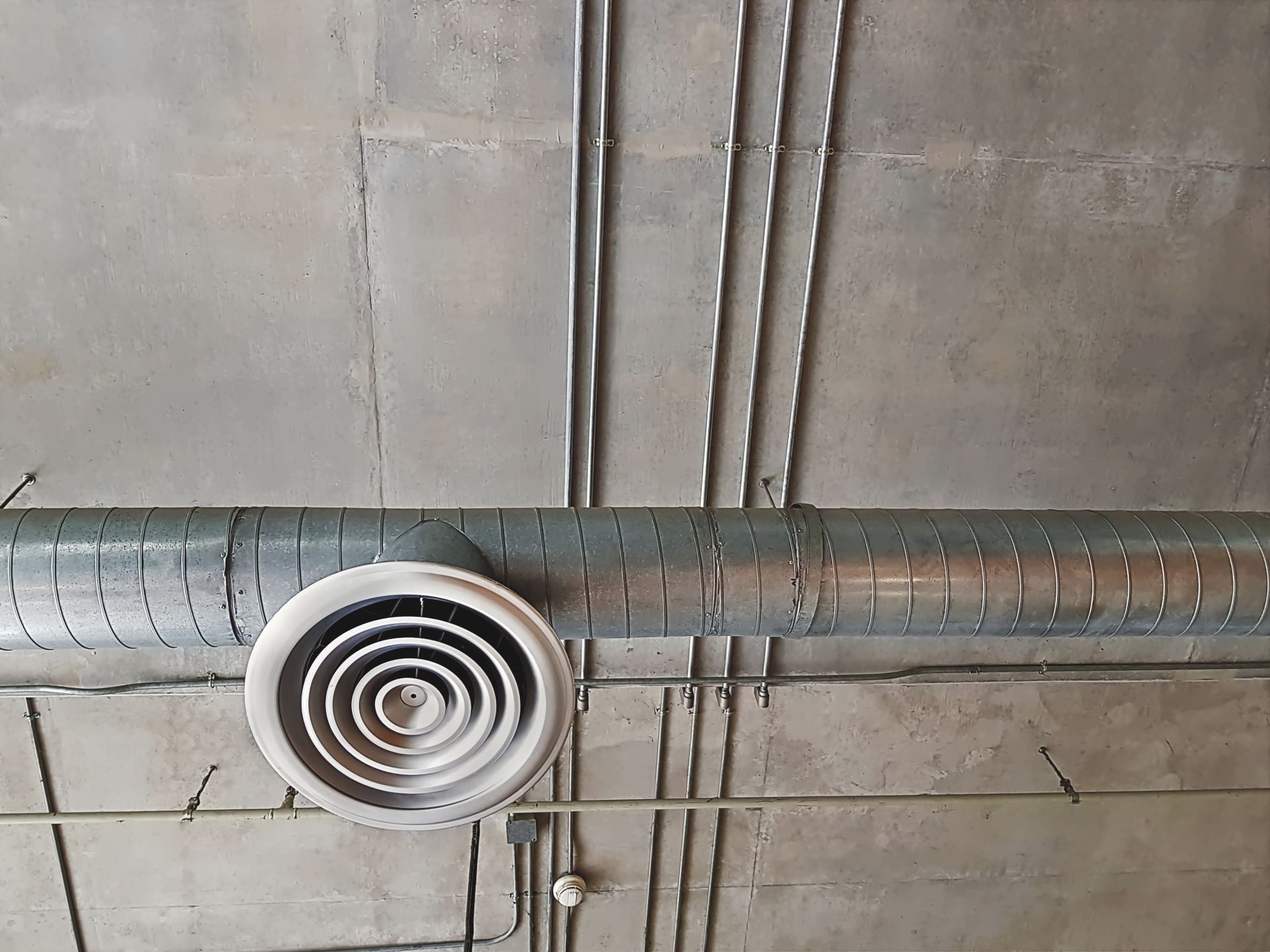

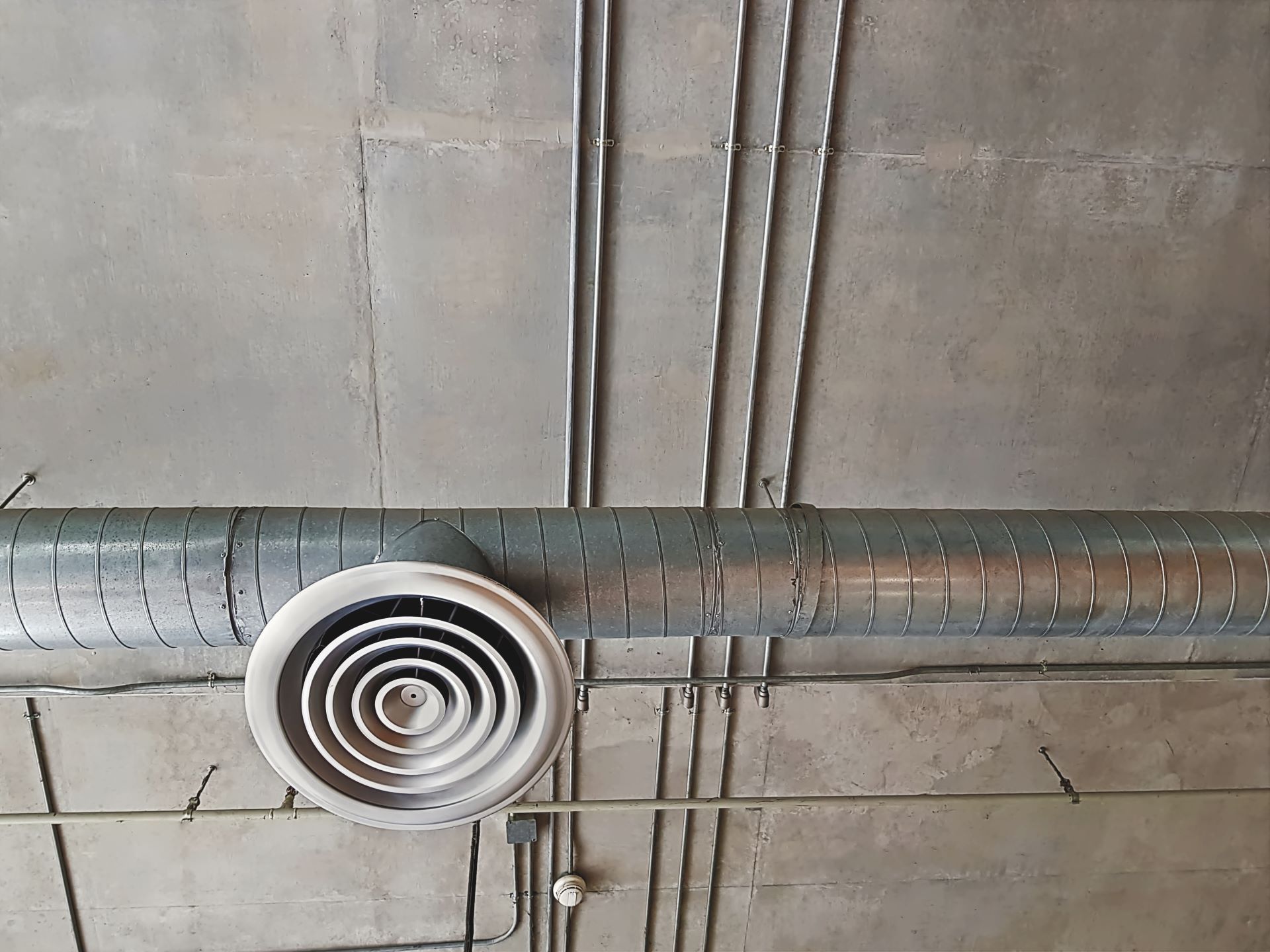

A Brief Overview of the HVAC System

The system consists of two constant volume exhaust fans each located in a dedicated penthouse on the roof. Each fan exhausts air through a heat recovery coil and then to the exterior through a louver in the penthouse. Both heat recovery coils were cleaned in this study. The exhaust ductwork extends to the first floor to serve general exhaust and to service patient areas in the second, third, fourth, fifth and sixth floors. Approximately 25% of the ductwork on each of the second, third, fourth, fifth and sixth floors were cleaned in this project.

Age of the System Was Taken into Account

The data presented in this report is based on measurements take during the cleaning as well as information from the original design. In a system of this type and age, the overall efficiency would naturally decrease over time. Henderson Engineers estimated this natural decrease in their calculations to obtain the true value of the duct and coil cleaning process.

Before and After Testing Reveals Inefficiencies of a Dirty HVAC System

They modeled two scenarios: one at a higher static pressure based on the condition of the coils and ductwork prior to cleaning and one where the static pressure is lower based on the condition of the coil and ductwork after cleaning. In both scenarios, the airflow was kept constant to simulate a change in energy use. This difference in energy use (based on the pressure increase) demonstrates the inefficiencies of a “dirty” system.

The Dirt on Why Duct Cleaning Works

The reality in this case is that as the static pressure increases (debris builds up at the coils and in the ductwork), the airflow decreases and only minimal changes in energy usage occurs. Once the ductwork is cleaned, far less static pressure is seen in the system and the airflows in the system increase significantly. This is all done with a minimal change in energy usage. If the system was cleaned and then the fan speed reduced to represent the system airflows prior to cleaning, the energy calculated in this report would be realized (and seen in utility savings). Since the cleaning “credit” in this case is yielding higher exhaust airflows, the savings is measured in a higher performing system. These benefits include patient comfort, improving infection control, increasing patient and staff satisfaction, etc. that may be worth more to the hospital than the energy savings themselves.

The Conclusion – Cleaning Ductwork Improves the System’s Efficiency

Cleaning HVAC coils and ductwork not only had a measurable and positive impact on the efficiency of the system, but can increase the hospital’s ability to create a more sterile environment, and potentially increase patient and staff satisfaction, along with other long-term benefits.

If you need duct cleaning, call Midwest Duct Cleaning and experience the benefits of a clean HVAC system. Call (913) 648-5300 .

Blog Contact Form

Thank you for contacting us.

We will get back to you as soon as possible.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Please try again later.